1.What is modular AHU with multi functions?

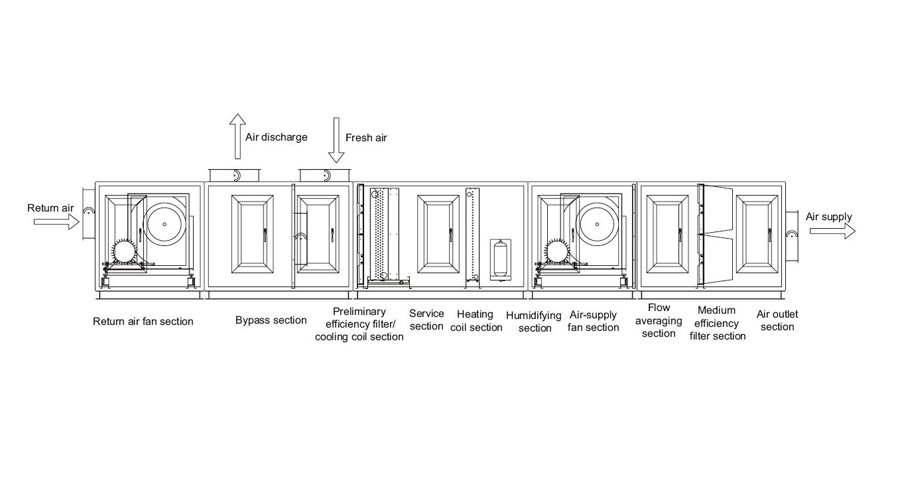

It is an air treatment equipment assembled from various air treatment functional sections. Suitable for air conditioning systems with resistance pressure greater than 100Pa. Eurostars AHU functional sections include such as air mixing, equalization, filter, coil, primary and secondary heating, de-humidification, humidification, supply air, return air, water spray, noise reduction, and heat recovery, etc.

The fresh air enters the air handling unit and is mixed with the indoor return air in the mixing section. The mixed air passes through the primary filter section G4 to move out dust and debris, and then passes through the medium-efficiency filter section F7 or F8 for secondary filtration to filter out smaller dust and debris. Then, air is cooled or heated through the cooling coil section or heating section to reach the required temperature point, and then humidified through the humidification section to reach the required humidity of the air conditioning system, and finally the air is supplied through the fan supply section for the rooms.

2.AHU multi functional sections

(1)Fresh and return air mixing section(if no fresh air, it is return air inlet flange):

The position of the fresh and return air inlet can be set at the end, the top or the left and right sides according to the design requirements. A regulating valve can be installed on the fresh air return inlets, and the actuator has three types: manual, electric and pneumatic, for the user selection.

(2)Filtration section:

There are two types of filters: primary efficiency filter G4 and medium-efficiency filter F7/F8/F9. G4 filter is non-woven washable plate type, F7 filter is bag type, it can be optional installed with pressure sensor to indicate the filter clogging with PLC controller.

(3)Fresh exhaust section (also known as flat-top air distribution mixing section):

There is a return air damper in this section, and an exhaust air outlet and a fresh air inlet are set on the top of the section, and a regulating valve is equipped. When there is a return air, it is used to discharge part of the return air, so that the fresh air and the return air are mixed in the required proportion; when the DC system is used in the transition season, the return air damper should be closed, and the exhaust damper and the fresh air damper should be fully opened.

(4)Heat recovery section

It is used for cross-distribution mixing and exhaust heat recovery in the dual-fan system. There is a primary air return damper in this section of the box, and the top is an energy recovery device. It is a kind of indirect cooling (heating) fresh air by using the cold (heat) of the exhaust air. The fresh air passes through the plate-type energy recovery device to recover the sensible heat of the exhaust air about 60% of the energy. At the same time, the exhaust air and the fresh air are not in direct contact, which is especially suitable for the heat recovery of the DC air-conditioning system that eliminates harmful indoor gases. When used as a DC system, the primary return air valve should be closed. A separate exhaust system should be set up in places with highly toxic gas, and this section should not be used.

(5)Access door section (maintenance section):

This section is used for the connection of the transition section and the lighting for the internal maintenance of air handling unit. there must be an intermediate section before the filter section, before and after the cooling section, the heating section, and the muffler section.

(6)Secondary air return section:

The middle section for connecting the secondary air return, the top can be equipped with a regulating valve, equipped with manual, electric or pneumatic regulating, which can be selected by the user. This section can also be combined with the blower section.

(7)Coil section:

The coil section adopts the copper tubes with four, six and eight rows of tubes and aluminum fin. The mechanical tube expansion form ensures the contact performance of the heat exchanger. The heat exchanger is divided into two types: fixed type and rotary type. Users can choose one according to their needs. The heat medium is steam or hot water.

3.Classification of modular AHU

(1)According to the structure type, it can be divided into horizontal type, vertical type and ceiling type;

(2)According to the usage, it can be divided into standard units, fresh air units, purification units and special-purpose units (such as rooftop units, subway units and computer room-specific units, etc.);

4.Installation requirements for modular AHU

(1)The assembly of each functional section of modular air handling unit should comply with the sequence and requirements specified in the design.

(2)Air handlers should be cleaned, and there should be no debris in the box.

(3)The air handling unit should be placed on a flat foundation, and the foundation should be higher than the ground level of the machine room.

(4)The condensate discharge pipe at the lower part of the AHU should have a water seal, and the connection with the external pipeline should be correct.

(5)The connection between the functional sections of the multi functional AHU should be tight, the whole should be straight, the access door should be opened flexibly, and the waterway should be smooth.

1.What is modular AHU with multi functions?

It is an air treatment equipment assembled from various air treatment functional sections. Suitable for air conditioning systems with resistance pressure greater than 100Pa. Eurostars AHU functional sections include such as air mixing, equalization, filter, coil, primary and secondary heating, de-humidification, humidification, supply air, return air, water spray, noise reduction, and heat recovery, etc.

The fresh air enters the air handling unit and is mixed with the indoor return air in the mixing section. The mixed air passes through the primary filter section G4 to move out dust and debris, and then passes through the medium-efficiency filter section F7 or F8 for secondary filtration to filter out smaller dust and debris. Then, air is cooled or heated through the cooling coil section or heating section